https://www.youtube.com/watch?v=9Jjdns2HIH4

Like many, I have a quantity various nuts, bolts, screws,

nails, washers, springs, pins, du-hickies and what-nots in my shop. Also, like many, I have a number of lidded

tackle box type organizers, loose bins, small cardboard boxes, jars and various

other storage containers that ultimately add up to a very loosely organized

storage system. Of course, after

searching through them for twenty minutes looking for the specific part I need,

I find it just after I get back from picking one up at the hardware store.

It is worth the investment in money and time to get all

these small parts organized. In the interest

of full disclosure, this is my second iteration of a central parts

organizer. The first was essentially a

cabinet that houses those plastic lidded organizers. It was a significant improvement and made a

big difference in my shop. In fact, I am

currently still using it. However, it is

woefully inadequate in the amount of bins and I find the design cumbersome and

restrictive because to get 1 part you have to pull out a organizer with many. This discourages me when it comes time to put

parts back in its rightful place.

Therefore, I am building a larger cabinet with drawers and

many interchangeable sizes of bins that can be pulled out individually. I sat down and did some calculations and

discovered I need somewhere North of 600 bins.

The parts organizer cabinet and the plastic bins that fill it really

break out into two separate projects. I

am going to focus on the plastic bins here.

I went searching for bins and not only could I not find ones

I liked, but it was cost prohibitive. It

became clear I would have to make them.

I found a video online of a gentleman who made a bunch of bins for a

similar cabinet using a 3D printer. (I

will include a link to his excellent video below). However, I ended up ruling this out when I

discovered it took several months to 3D print all the bins and I don’t even

want to try to calculate how many spools of filament he must have gone through.

Ultimately, I decided to order 18”x24”x1/8” plastic sheets

and cut the bins on my CNC router. The

sheets allow me to size the bins and cut the quantities to my specifications. The CNC time is about 20 minutes for each

sheet and assembly and finishing time averages out to well under a minute per

bin. According to my calculations, it

will take somewhere around 18 hours which is a whole lot better than 3 months.

I decided to make the base unit of the bins 2”x2”. All other size bins will be an expansion of

that base unit to allow me to mix and match based on the part size. For example, 2x4s 2x6s 4x4s 4x6s, etc. The bins are 1 ½” tall. At this point, I have cut 4 sheets of plastic

working the bugs out and have ordered the remaining 50 sheets of plastic.

The first thing to do was to lay out my design for the

CNC. The prototype design cuts 12 2x2s

and 3 2x4s. (Fig. 1)

The first tool path was a drill pattern drilling holes in

waste areas of the sheet. Once those

were drilled, I used screws to screw the sheet down to a sacrificial MDF

machine bed on the CNC router. This

keeps the sheet from bowing up and down in the middle which significantly

affects the cut depth. Additionally, I

am able to remove the clamps enabling me to maximize the yield and eliminate

the possibility of the cutting head running into one of the clamps. (Fig. 2)

The first run I created utilized the 90-degree v-bit for all

of the cutting. I figured having a

beveled edge at the top of the boxes would not be a problem and it would save

me from changing the bit on every sheet.

(Fig. 3) However, after the first

runs, I decided I didn’t like the way it turned out and opted to use a ¼”

spiral upcut bit to cut the tops. The v-bit

cuts on the 4 bottom corners are slightly more shallow so the plastic holds

together but will bend up to form the sides later. The parallel shallow cuts near the top of each

side are designed to give your fingers some purchase when trying to pull a bin

up and out of its tray.

By properly setting the cut depths on the CNC, I was able to

separate the flat box “blanks” from the sheet by just pressing them though,

although, there were a few instances where I used a razor knife to clean up the

edge. (Fig. 4)

Some scientific testing was called for at this point to

determine the best glue for the job. I

was hoping to find a glue that would bond the plastic sufficiently in a single

stage, but I ultimately ended up selecting the tried and true 2 part epoxy even

though it takes a bit longer. (Fig. 5)

In the test phase, I placed the blank on a small block of

wood and used a heat gun to warm up the plastic blanks until they started to

fold under the weight of the sides. This

means the plastic is pliable enough to fold. (Fig. 6) Later, to speed up production, I warmed them in

an oven at 200 degrees so I could warm a lot at once.

After mixing the 2 part epoxy, I used a glue spatula to

place glue on all the surfaces that will be bonded when I fold up the

boxes. (Fig. 7)

Once the epoxy is on, I just folded the boxes up and placed

a rubber band around them to act as a clap while the epoxy cures. (Fig. 8)

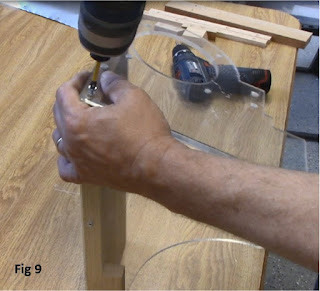

Once the epoxy has set, it is time do use the belt sander to

lean up the tops, any rough edges and any epoxy that may have squeezed out of

the seams. (Fig. 9) The

completed boxes are strong and ready to be used. (Fig. 10)

Link to Alexandre Chappel video Parts cabinet Video: https://www.youtube.com/watch?v=CHFK5sY8ToE&list=LL&index=9&t=383s

Rod Gunter is

Operations Manager at Gunter Building Solutions and has over 20 years of

experience in the homebuilding and cabinetry industries. Rod has been responsible for building over

200 homes above the $500,000 price point.

Rod has trained large groups including all the major home centers on

selling skills, construction techniques and sustainable natural wood

products. Rod resides with his family in

Holly Springs, North Carolina. Gunter

Building Solutions owns WoodAirGrille.com which manufactures wood return air

filter grilles and wood return air vents.