I know a lot of shops fight the same constant battle that I

do against dust. One of the biggest

offenders in my shop is the table saw.

This tool is used extensively every single day and as much as I like the

table saw I have, the factory dust collection ports seem to be a bit of an

afterthought in the design and leave a lot to be desired. Most moderately priced table saws I have

owned and considered purchasing seem to have similar shortcomings in dust

collection. My saw, in particular, has a

plastic hood that rides over top of the riving knife that is supposed to keep

dust from flying up and redirect it to the dust port under the blade. However, due to the open clearance needed for

the tilt mechanism, it is wide open underneath and half the dust makes it into

the dust collector basically by chance and the rest ends up in the air or on

the floor. To make matters worse, it is

only a 2 ½” port.

The solution I came up with is designed to extract a very

high level of dust with rip cuts under 3” wide and 1” thick. In my shop, the vast majority of cuts are

rips under 3” in ¾” material so it will not work well for cutting large plywood

panels, wide boards, crosscuts or thick material. However, the hood is attached to the rip

fence and simply slides out of the way, usually without having to be

removed. The factory hood is simply

tilted back down over the blade. If the

hood does need to be removed it is a simple matter of loosening 2 threaded

knobs. My saw is set up with a 2” wide x

3” tall rip fence with a 1 ½” x 1 ½” l shape rider made of ¾” plywood and a

1/8” angle aluminum face. The dimensions

given are built around this so you may need to modify as necessary to fit your

machine or needs.

Using the new hood has been a tremendous difference. With the factory set up I estimate 50% of the

dust was being collected. With the new

hood, I estimate conservatively 90% of the dust is being collected. There is a noticeable difference in the

entire shop.

Far and away the most intricate part of the build is the

clear acrylic face. The main face part

and two tilting blade covers were cut from a single 18” x 24” sheet of ¼” thick

acrylic. (fig 1) I made 2 of the tilting blade covers simply

to have a spare because I can see this part potentially wearing out or getting

damaged over time. The parts were cut

with a CNC router set to a high travel speed and low RPM. However, this can certainly be cut with more

traditional tools like a jig saw and a drill.

I have attached a scalable drawing.

(fig 2) I will also be happy to

share the V-carve CAD drawing and .tap toolpath file. Just send me an email or ask in the comments

section.

The acrylic needed to be bent at a 90ׄ° angle. It could also be glued together as 2 pieces

but I prefer the cleaner method of bending the acrylic. (fig 3 & 4) I used a shop built acrylic bending jig. There are many tutorials on how to easily

build one of these with a piece of resistance wire.

The wood pieces that need to be cut are fairly

straightforward. I used ¾” red oak, but

only because that is what I happen to have lying around. Any ¾” hardwood will work fine. (fig 5)

Below is the list of finished

material:

Top Board – 6” wide x 11 ¾” tall. Both sides cut on a 20° angle

parallel to each other

Base board – 2” wide x 13” long

Back support – 2” wide x 2 ¼” long. One side cut on a 20° angle so the 2 ¼” side

is the short side

Filler Post – 1” wide x 2 ¾” long. Cut across the 1” side at 20° angle so the 2

¾” side is the short side.

Front connector – 2” wide section of 1 ½”x1 ½” right angle

aluminum. I cut one of the legs down to

1” purely for aesthetics. It is not

necessary. Drill 2 holes matching the

two holes in the acrylic directly below the 4” hole.

With the basic pieces cut there is one other component that

needs to be addressed before assembly begins.

The acrylic blade flap (fig 6) will be held down with a thumb screw

which will need a stable set of threads to screw into. To accommodate this, a 1” x 4” piece of the

¾” oak stock was used to provide a base for a threaded insert. (fig 7)

After drilling and placing the threaded insert it was bolted to the

bottom of the Top board out of the way of the blade. (fig 8).

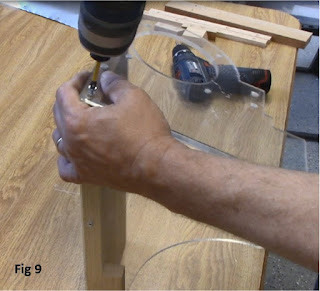

Assembly of the basic structure starts with attaching the

top board to the acrylic face with #6 x ¾” wood screws making sure the head of

the screw is below the surface of the acrylic allowing the blade flap to rotate

upward without obstruction. (fig 9)

The back support will need to be attached to the base board

2” from the end of the board with #6 1 ½” screws. This allows enough room on the base board for

the rear mounting bolt and threaded knob. Then the base board assembly is attached to

the acrylic face with #6 1 ½” screws in the back and #10 1 ¼” in the front

making sure to place the right angle aluminum in front of the acrylic plate (fig 10)

The filler strip is then attached alongside the back support

with #6 1 ½” screws. (fig 11)

The next step is to attach the dust port to the acrylic

face. I used a round 4” flanged dust

port found at any woodworking supply store.

Hold the port in place and using the mounting holes in the dust port as

a template drill through the acrylic.

Using ¾” long machine screws with washers, lock washers and nuts, attach

the dust port to the acrylic face. (fig

12)

To make the port channel on the fence side of the hood I

elected to use a 20” slice of 14” wide light gauge galvanized metal roof

flashing because it has about the right balance between malleability and

rigidity. There needs to be a crease on

about a 20° angle near one side. Using a

sheet metal brake, I found it advantageous to crease it along the natural curl

of the metal from the roll. (fig

13) This light sheet metal can also be

creased by clamping 2 scrap boards together to sandwich the metal and then

pressing the seam with a third board.

Using a pair of pliers, sheet metal pliers are ideal,

flatten the crease back out of one end of the metal perpendicular to the seam

at least an inch from the edge. (fig 14)

Mounting the sheet metal to the hood requires using some form

of clamping strip. I used ¾”x1” strips

of wood, but metal or aluminum bar stock would work well too. The lengths are 11 ¼” for the bottom, 11 7/8”

for the top and 2 ¼” for the side cut on a 20° angle. (fig 15)

Place the sheet metal on the fence side of the hood so the

crease in the metal meets the angle in the acrylic face below the dust

port. Secure it with a few screws

allowing the metal to extend beyond the edges of the hood. (fig 16)

Form the metal into a cone shape and mark where it meets the

edges of the dust hood. (fig 17 &

18)

Once the metal has been trimmed with a pair of tin snips or

shears and the edges filed, attach it to the dust hood using the clamping

strips. (fig 19 & 20) A little

silicone sealer along the edges of the metal and any other gaps will make a

difference.

Attach the blade flap with a ¼” x 1” bolt secured with a

lock nut through the front hole and a ¼” x 1” thumb screw in the rear hole

tightening into the threaded insert.

(fig 21)

To mount the hood on the fence, it was placed on the fence

and marked for ¼” thumb screws. Once

drilled, t-bolts were placed in the fence and tightened with threaded

knobs. (fig 22 & 23)

A “Y” connector is used to split the dust collection between

the factory port at the bottom and the new port on the dust collection

hood. (fig 24 & 25)

The blade flap can be tilted up and out of the way to slide

the fence by loosening the thumb screw.

(fig 26)

Here is a video link

Rod Gunter is

Operations Manager at Gunter Building Solutions and has over 20 years of experience

in the homebuilding and cabinetry industries.

Rod has been responsible for building over 200 homes above the $500,000

price point. Rod has trained large

groups including all the major home centers on selling skills, construction

techniques and sustainable natural wood products. Rod resides with his family in Holly Springs,

North Carolina. Gunter Building

Solutions owns WoodAirGrille.com which produces wood return air filter grilles

and wood return air vents.